Clients & Segments

We are serving our clients across the globe, trusting us for high-precision

castings, timely delivery, and technical support.

At Mahendra Foundry Division

Part of the legacy-rich Mahendra Group, the Mahendra Foundry Division blends six decades of engineering heritage with modern innovation. We specialize in Grey and SG Iron castings that power industries like agriculture, automotive, pumps, and general engineering.

We are on a mission to harness the skills and knowledge of our people to make Mahendra Foundry a global leader in cast iron solutions — enabling our customers to operate with a lasting competitive edge through continuous innovation and quality.

Segments We Cater To

Infrastructure

Our foundry spans 5 acres with 30,000 sq. ft. of built-up space, equipped with advanced melting, molding, and finishing facilities. Designed for both scale and precision, the setup integrates automation with skilled expertise to ensure consistent quality, faster lead times, and reliable delivery that meets global standards.

Production Facilities

- Tri-Track Inductotherm Induction Furnaces – 3 units (0.5 MT each, 550 KW Tri-Track) with a total capacity of over 30 MT of iron per day.

- ARPA 300 Molding Machines – 400x520x150 mm & 520x520x150 mm heights.

- Savelli Mechanized Sand Plant – Fully automatic for efficient sand preparation.

- Cento SINTO High Pressure Molding Machine – 660x508x200 mm.

- Part Weight Capability – From 0.25 kg to 50 kg.

- Core Making Facilities – Cold Box Core Shooter (5 kg & 10 kg), Oil Core, and CO₂ Core Making.

- Auxillary Equipment – Sand hoppers (80 MT × 2), sand cooler with vibrating system, ambient control equipment for pollution control.

- Shot Blasting Machines – Hook type (250 & 500 kg) and Drum type (250 kg).

- Well-equipped Fettling Shop.

Production Facilities

Quality You Can Trust

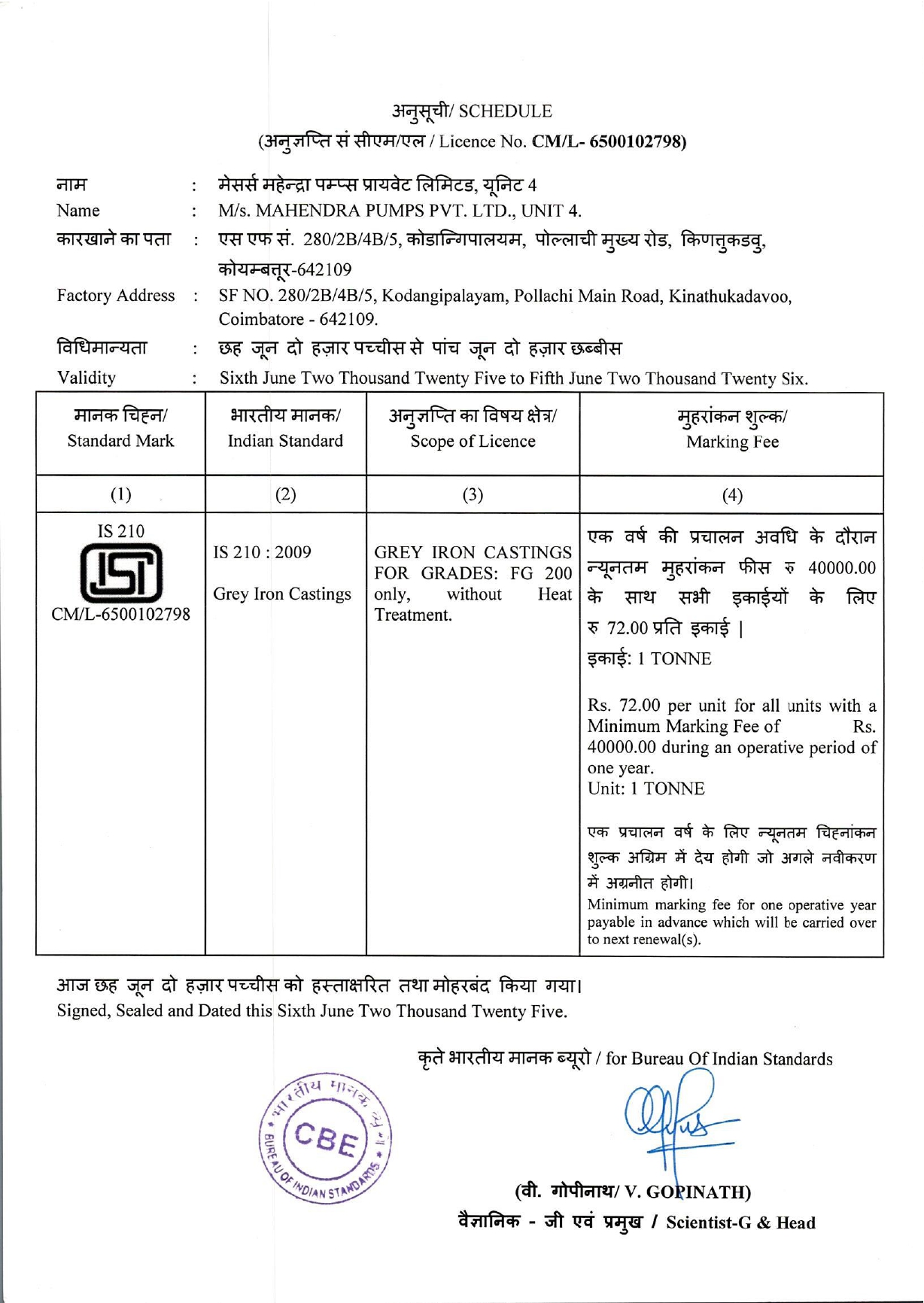

- ISO Certified since 1998 – Ensuring globally recognized standards.

- Spectrometer Testing – Complete analysis of all 24 iron-based elements.

- In-House Labs – Sand Testing Lab Facility, Chemical Testing Facility, and Mechanical Properties Testing Facility.

- Mechanical Testing Equipment:

- A. Brinell Hardness Tester (3,000 kg)

- B. UTM (40 Tons)

- C. Image Analyser

Quality You Can Trust

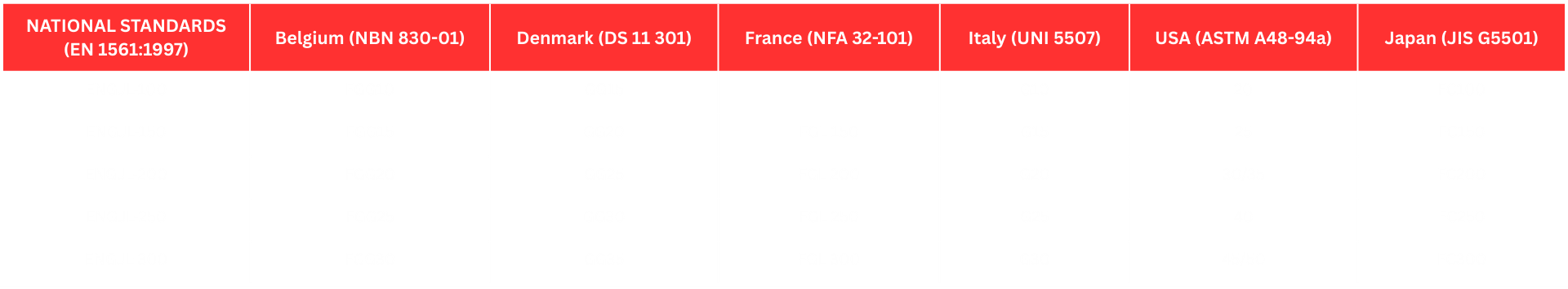

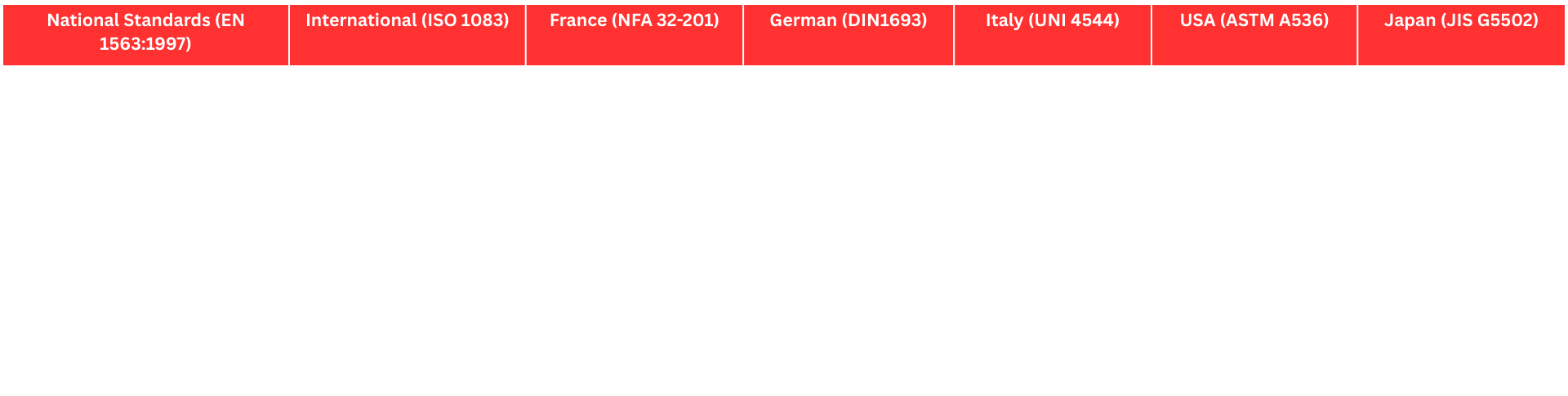

Grades for Every Application

- Mahendra Foundry caters to diverse industrial needs.

- Providing cast iron solutions across a wide range of grades and specifications.

- Tailored to meet performance and durability requirements.

Grades for Every Application

Grey Iron Grades

Ductile Iron Grades

Our Products

Anchor Buster

SG 550/6

Anchor Buster

Pump Casing

FG 260

Pump Casing

Cover Casing

FG 200

Cover Casing

2" Body

FG 260

2" Body

Casing

FG 200

Casing

Bearing Housing

FG 260

Bearing Housing

Motor Body

FG 200

Motor Body

Flange

FG 200

Flange

Segment Carrier

FG 260

Segment Carrier

Drive Wheel

SG 450/12

Drive Wheel

Bearing Housing

FG 260

Bearing Housing

Segment Carrier

FG 260

Segment Carrier

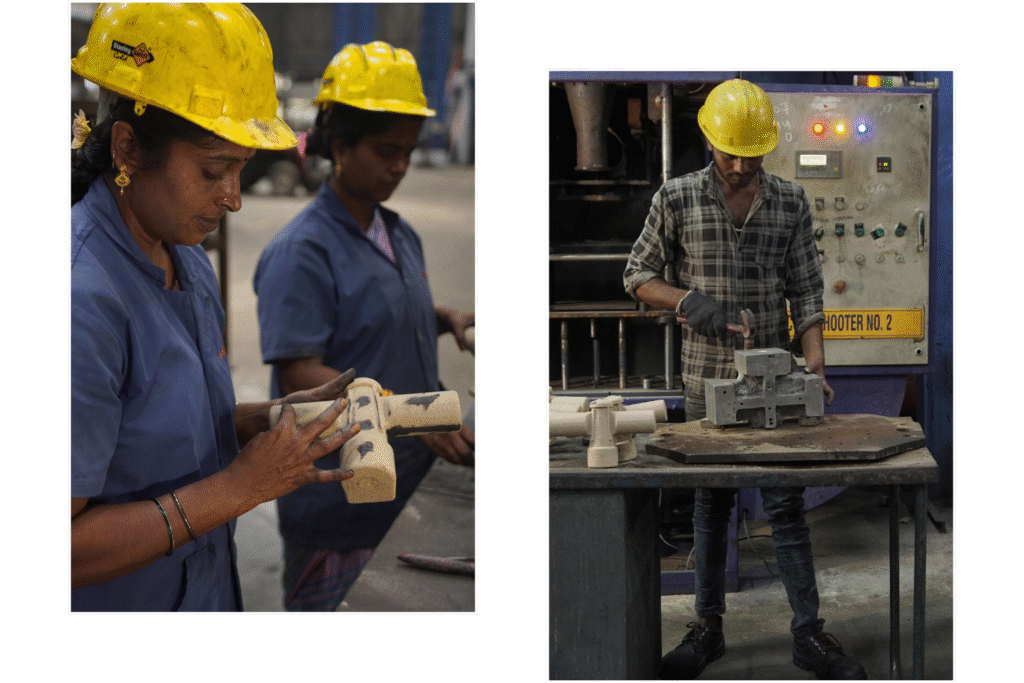

Our Gallery

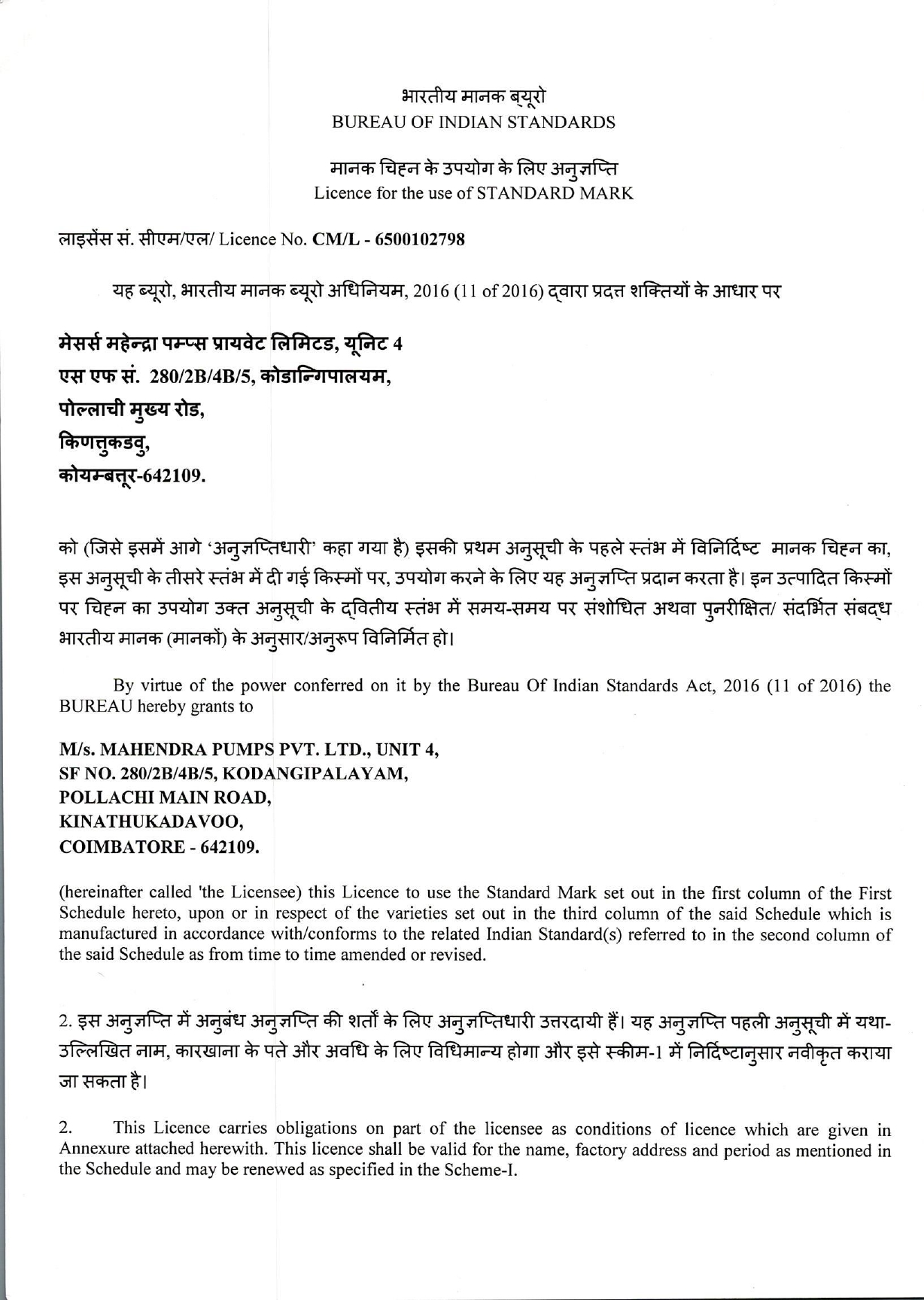

Our Certificates

Testimonials

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam porttitor tortor turpis, vel semper massa hendrerit eu.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam porttitor tortor turpis, vel semper massa hendrerit eu.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam porttitor tortor turpis, vel semper massa hendrerit eu.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam porttitor tortor turpis, vel semper massa hendrerit eu.

Safety & Sustainability

At Mahendra Foundry, we also place the highest emphasis on team safety and well-being. Our facility is fully equipped with modern safety systems, regular training programs, and protective gear — ensuring a secure, efficient, and compliant working environment across all operations.